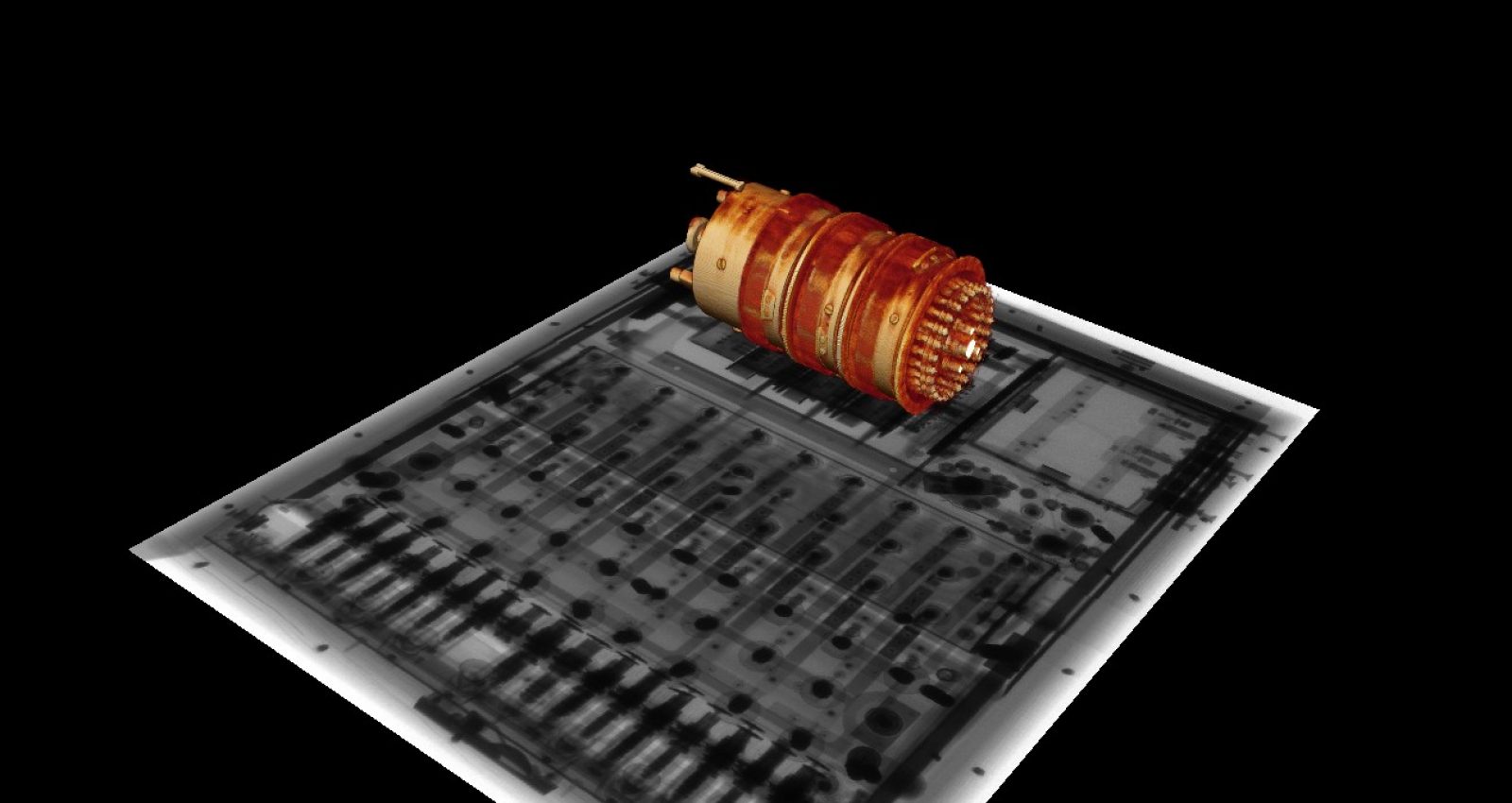

National X-ray Computed Tomography (NXCT) is the National Research Facility for lab-based X-ray computed tomography

Background

Established in November 2020, the NXCT is a £10m investment from the Engineering and Physical Sciences Research Council (EPSRC) in capital and recurrent funding to support research in the UK. We bring together world-leading capability in lab-based X-ray Computed Tomography (XCT) from the universities of Manchester, Southampton, Warwick, University College London and Diamond Light Source.

The NXCT Hub in Manchester is hosted by the Henry Royce Institute for advanced materials. The facility includes a dedicated space on the second floor of the Royce Hub building to host a Data Visualisation and Analysis Support Centre for new and experiences users alike.

As the UK’s national research facility, our mission is to provide access and expert support for both academia and industry, embracing first-time users and more experienced researchers to run cutting-edge 3D and 3D time-lapse imaging experiments

We provide an unparalleled combination of 3D imaging facilities and data analysis, research knowledge and technical experience to support users that have never worked with X-ray scanning before and help advanced users conduct exciting new experiments. Together, the five partners provide a unique and diverse shared capability to the UK. The NXCT provides:

- access to state-of-the-art X-ray instruments

- technical support for new and existing users

- the expertise to design complex experiments

- the infrastructure and resources to analyse 3D and 4D data.

Access and Enquiries

Potential users are encouraged to make general enquiries and apply to use NXCT equipment through this website. If you are interested in finding out more about what the NXCT can offer, please do make an enquiry via the Contact Us page. From this, we can discuss the specifications of your project and advise on the services we can offer. We can also provide the information needed to support grant proposals.

We welcome enquiries from the industrial community and we are keen to work together. If you are an SME you can get into touch via the NXCT enquiry form here to discuss the further support we have available.

NXCT’s mission is to improve X-ray CT accessibility for UK researchers. To support this, we have established a ‘Free Beamtime Access Scheme’ which encourages small and medium-sized enterprises (SMEs) to engage with XCT technology, facilitating any research, teaching, or public engagement projects that will benefit from X-ray CT imaging facilities and expertise. Please visit the Accessing Equipment page to find out more about eligibility and how to apply.

History

Now part of the NXCT at The University of Manchester, The Henry Moseley X-ray Imaging Facility (HMXIF) was established in 2008 by Professor Philip Withers, going on to become one of the most extensive suites of 3D X-ray imaging facilities in the world. In 2014, The University of Manchester was presented with the most prestigious award in UK higher education, the Queen’s Anniversary Prize for Higher and Further Education (2012-2014) for “New Techniques in X-Ray Imaging of Materials Critical for Power, Transport and Other Key Industries”.